为进一步丰富校园文化生活,引导同学们树立文化自信意识,加深对本土文化的了解和热爱,九州网页版外国语学院学子走进家乡的传统“非遗”,挖掘家乡“非遗”文化的现代传承,用英语展现与传播贵州非物质文化遗产的魅力。

下面,让我们的同学与大家一同分享“非遗”之美

Brewing Technology of Maotai Liquor

The brewing technology of Maotai liquor is a traditional method that has been recognized as an intangible cultural heritage since 2006.

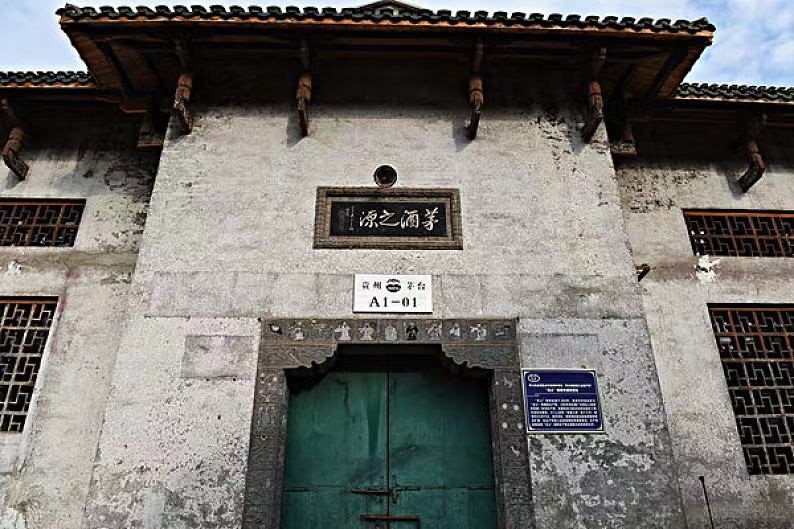

Maotai Town

Maotai Town, where the liquor is produced, is located at 105E 27N and is surrounded by mountains and rivers, offering breathtaking scenery. The town's location in a valley area with warm winters, hot summers, and a high annual average temperature, along with low relative air mobility, creates an ideal environment for the growth of brewing microorganisms.

High-quality wheat

To make Maotai liquor, high-quality wheat is processed into koji powder, which contains enzymes such as amylase, saccharifying enzyme, and protease. This powder acts as a catalyst for forming the flavor components of Baijiu.

Local red sorghum

Maotai Town uses local red tassel sorghum as the raw material for brewing Maotai liquor. This sorghum has high amylopectin, high tannin content, small hard endosperm particles, and is resistant to steaming, boiling, and turning.

Chishui River

Water is a crucial ingredient in the brewing process, and the water quality of Chishui River Cave Spring is excellent. It is rich in various minerals and trace elements that are beneficial to human health, and the water body is not polluted.

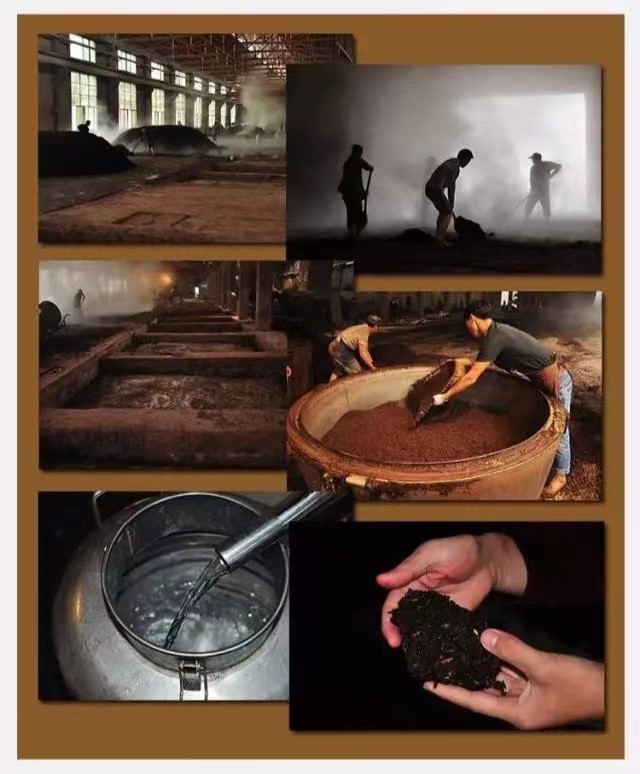

The first step: make koji

The first step in the production of Maotai liquor is to crush the wheat and add mother koji and water to create koji embryos. Rice straw is then used to ferment the mixture in the warehouse for 40 days. After being stored for 60 months, the koji is removed and used in wine production.

The second step

(1) Feeding Stage: The second step involves the feeding stage, which begins with two stages: sanding and sand making (where “sand” refers to sorghum). After being crushed, the sorghum is heated and moistened with water. The next day, it is steamed with other grains, spread in a steamer for drying, then mixed with koji and tail liquor to create an even stack that meets the process requirements. After 30 days of fermentation in the cellar, the cellar is opened to remove the fermented grains, which are then mixed with sand. The above process is repeated starting from the steaming of grains.

(2) Distillation Stage: The distillation stage comprises seven rounds, each of which involves spreading, adding koji, stacking, aging, and distilling. The entire winemaking process encompasses a total of nine instances of steaming, eight times of drying, adding koji, stacking, and aging in the cellar, as well as seven rounds of wine extraction, resulting in a one-year production cycle.

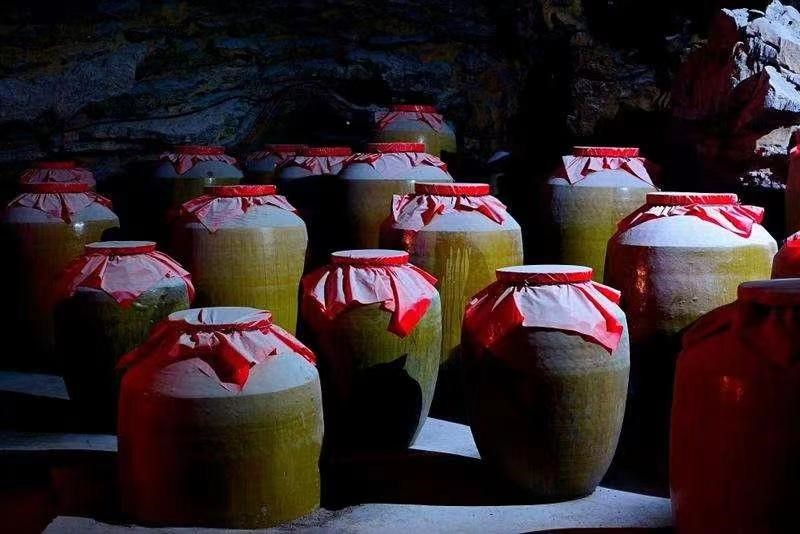

The third step: storage and blending

Base liquor is stored in a ceramic jar through three typical steps: sauce aroma, mellow sweet aroma, and cellar bottom aroma. Base liquor of different rounds, types, alcohol content, and age is blended and stored in a ceramic jar. The storage and blending process shall last for at least three years.

Last step: inspection and package

After the blended wine has passed the inspection, it is packaged in an opaque container before leaving the factory.

"The path to all benefits goes hand in hand with the times." The brewing technology of Maotai liquor is a time-honored tradition that has been passed down for generations. It is a testament to the profound heritage of Chinese culture and the people's dedication to excellence.

文中图片来源网络,如侵权请联系删除。

文字:徐文倩

指导教师:王雪丽

稿件审校:周丽

一审:黄超禹

二审:杜玉红

三审:徐焱